New possibilities. Unlimited applications.

The ability to “3D Print” high-performance passive electronic ceramics and metals opens a world of exciting possibilities for the future of manufacturing.

The ability to “3D Print” high-performance passive electronic ceramics and metals opens a world of exciting possibilities for the future of manufacturing.

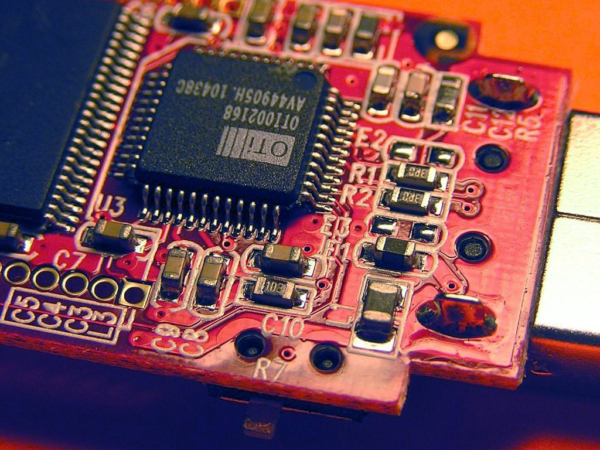

Just like in the 1960s, discrete, passive components are soldered onto a printed circuit board in slow, large-scale and expensive processes requiring large facilities and lots of people. Small runs are cost prohibitive and design improvements or corrective actions are slow to implement.

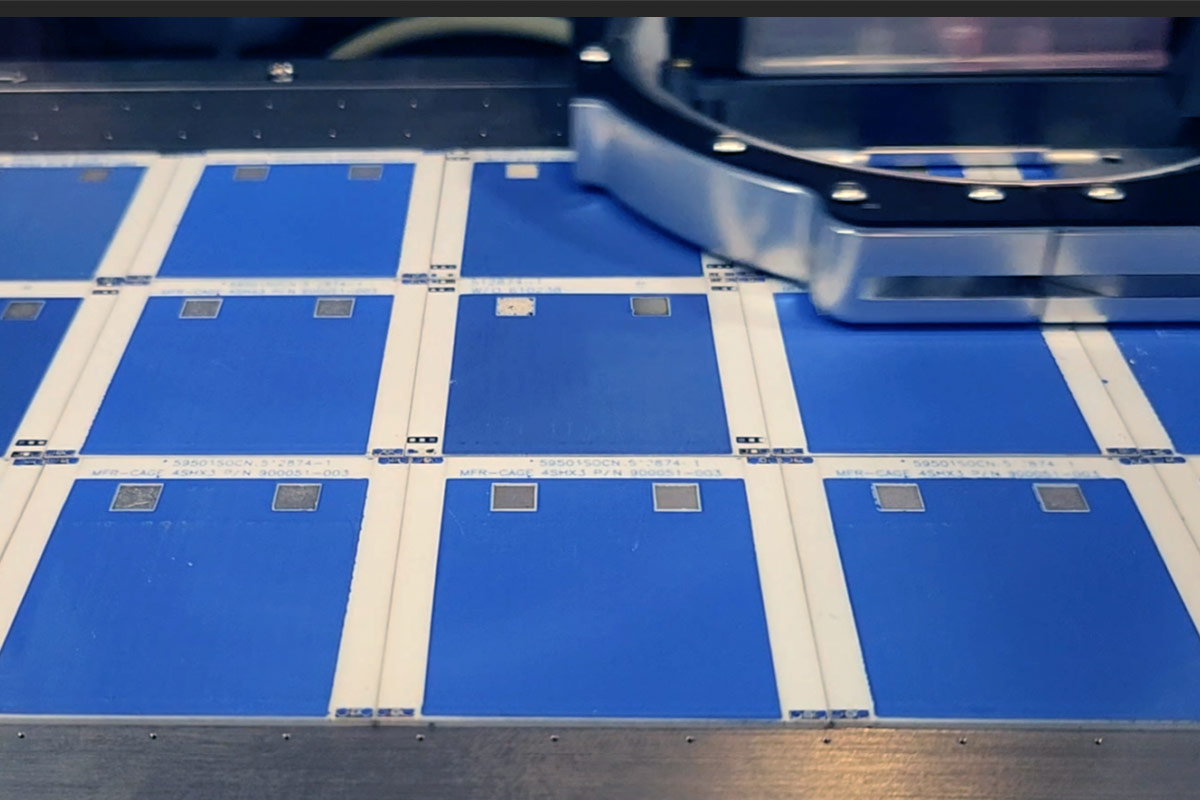

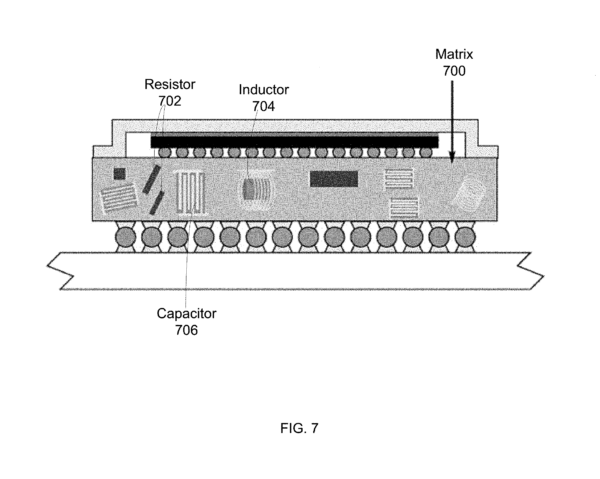

Our patented Additive Manufacturing Technology allows us to “3D Print” passive, discrete components at any scale, saving enormous resources and freeing product designers and engineers to make rapid iterations and improvements. Fabricating in 3 dimensions opens up a world of possibilities.

Capacitors are instrumental in electronics devices using semiconductors, as well as other devices requiring non-specialized capacitors such as LED lighting

Capacitors are used by enhanced oil and gas recovery companies to deliver deep-hole massive seismic pulses to measure oil reservoir status

The medical applications of MLCCs are predominantly in implantable devices that stimulate nerves, such as cardiovascular control, cochlear implants, etc.

Capacitors are used in aviation to support the lighting, power supplies, amplifiers, etc.

Mostly housed in the PCB of mobile devices, as well as the I/O, microphone, display, buttons and camera flash

Capacitors are supplementing batteries to extend the driving range of electrical vehicles

Vq Research has been a subcontractor in a DARPA project and worked with a partner company to supply our MLCC technology to a critical national security project.

The principal contractor in the DARPA project identified Vq Research as having unique MLCC IP that would be critical to carrying out this DARPA project and enabling a vital national security (and global security) anti-crime and anti-terrorism technology that is forecasted by DARPA to be worth multiple billions of dollars in revenue.

In the past, drilling operations have maxed out at temperatures of ~150°C to 175°C, but declining reserves have motivated the industry to drill deeper. Temperatures in these wells can exceed 200°C, causing conventional capacitors to fail.

Rigs cost over $1 million a day to operate, so down time to replace a failed capacitor is extremely expensive

(Source)

The specialized parts used in satellite technology often require extensive testing and expensive iterations. Ceramic capacitors produced using conventional methods have plagued defense program satellites costing hundreds of millions of dollars to repair and replace.

Further Reading:

New GPS Satellite’s Delivery Slips Again Over Untested Component

Lockheed Hit by U.S. Air Force for More GPSIII Satellite Flaws