3D Printing High Performance Electronic Components

Additive Manufacturing Technology (“3D Printing”) is finding its way into all corners of materials production and everyday life. Complex metal parts, ceramic parts, dental implants, even wood and concrete can be rapidly designed, prototyped and manufactured. Bioscience and healthcare is being revolutionized with 3D printed tissue, organs, and bone. Additive manufacturing is even a new platform for cuisine and art.

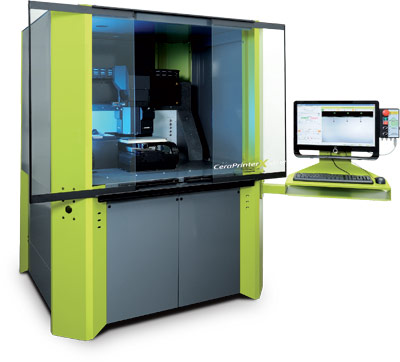

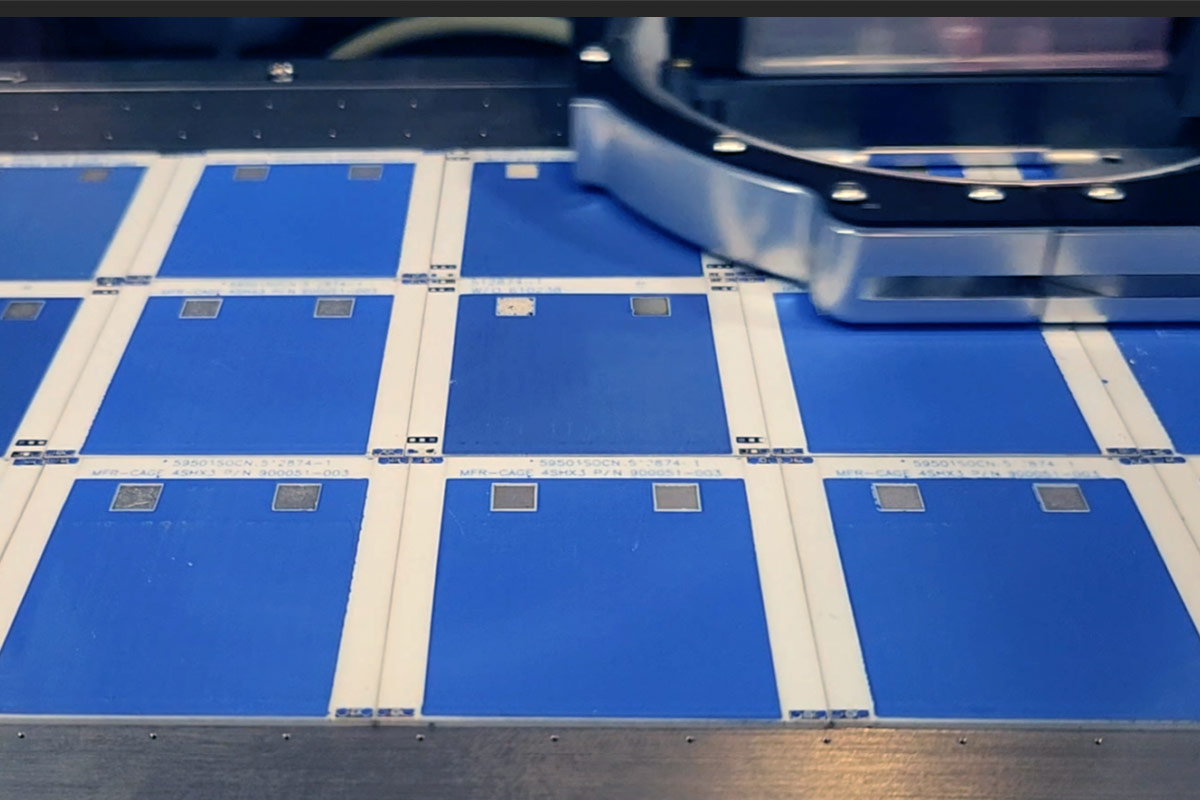

VQ Research is advancing Additive Manufacturing Technology to produce high-performance electronics using ceramics and thick film metals. For example: Perovskite ceramic-based capacitors, Ferrite-based inductors and circulators, as well as Cermet and ruthenium oxide-based resistors.